Hardware

Electronics, History, Symbiosis

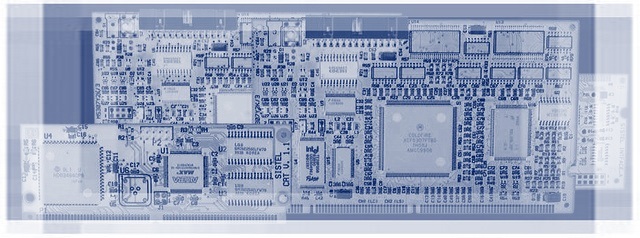

SISTEL has always autonomously designed and realised electronic systems for quality control with the goal of creating dedicated Hardware which always represents the best compromise between cost, performance and reliability.

This type of design is commonly called "CUSTOM" design.

This type of design is commonly called "CUSTOM" design.

You can imagine the difficulties of designing CUSTOM Hardware. It requires specific knowledge for each product chosen, expensive equipment and many hours, sometimes months, of work. It is undoubtedly much easier to purchase a product which is already available on the market, but which does not provide the advantages of a CUSTOM product, first and foremost the performance and specific knowledge of the entire system.

SISTEL's first project for quality control in the cork field dates back to 1978!

In that period the available technologies certainly did not offer advanced Terminals, Editors, Compilers or Debugging systems like the ones we have today. A 16K memory bank was as big as two Motherboards in a modern PC and the processors, maximum 8-bit, went from 1 to 4 MHz.

With this infrastructure one might ask how it is possible to realise an optical inspection and quality control machine. Well, with a CUSTOM project this was possible!

The data coming from two cameras (at that time 32x32 pixel matrix) were converted to Digital by a chain of analogical comparers which placed the conversion inside the Shift Register before being stored in a memory through a counter. Today this is called A/D FLASH CONVERTER and is a single chip, but at one time it was an entire board. The data were then handled, not by a microprocessor, but by 4 microprocessors, carefully managed by a system of links which equally sub-divided the word to be performed.

This is the philosophy which we continue to work with today, that philosophy which, already in the late 1970's made technologies and optical inspection systems available to the cork industry which not even the wealthiest and most well known pharmaceutical industries had.

The mechanics are also completely designed and realised by us so that we can be 100% owners of our systems and so that we are able to make any modifications and/or developments which may become necessary.

When the mechanics need specific controls and movements, the hardware is designed to provide these controls, and when the Hardware needs specific movements and speeds, the mechanics are designed to meet these characteristics.

So we can speak of Symbiosis - a symbiosis which only someone who completely designs the entire system can realise.

Finally, the software which manages everything is obviously developed internally by us so that there is nothing which forces us to depend on third parties.

SISTEL's first project for quality control in the cork field dates back to 1978!

In that period the available technologies certainly did not offer advanced Terminals, Editors, Compilers or Debugging systems like the ones we have today. A 16K memory bank was as big as two Motherboards in a modern PC and the processors, maximum 8-bit, went from 1 to 4 MHz.

With this infrastructure one might ask how it is possible to realise an optical inspection and quality control machine. Well, with a CUSTOM project this was possible!

The data coming from two cameras (at that time 32x32 pixel matrix) were converted to Digital by a chain of analogical comparers which placed the conversion inside the Shift Register before being stored in a memory through a counter. Today this is called A/D FLASH CONVERTER and is a single chip, but at one time it was an entire board. The data were then handled, not by a microprocessor, but by 4 microprocessors, carefully managed by a system of links which equally sub-divided the word to be performed.

This is the philosophy which we continue to work with today, that philosophy which, already in the late 1970's made technologies and optical inspection systems available to the cork industry which not even the wealthiest and most well known pharmaceutical industries had.

The mechanics are also completely designed and realised by us so that we can be 100% owners of our systems and so that we are able to make any modifications and/or developments which may become necessary.

When the mechanics need specific controls and movements, the hardware is designed to provide these controls, and when the Hardware needs specific movements and speeds, the mechanics are designed to meet these characteristics.

So we can speak of Symbiosis - a symbiosis which only someone who completely designs the entire system can realise.

Finally, the software which manages everything is obviously developed internally by us so that there is nothing which forces us to depend on third parties.

Did you know that...

Microprocessors can be divided mainly into 3 families:

DSP, CISC and RISC

Without getting too technical, we can described the difference between these three families as follows:

DSP - Digital Signal Processor.

Microprocessors optimised to execute algorithms in an extremely efficient manner which allow handling of sampled signals.

These are particularly used in instruments of measurement where complex mathematical calculations are required such as a "Fourier Transform" or band filters for Multiplexers in the telephony sector or for analysis of Radar data, Sonar data, Spectra analysis, etc.

CISC - Complex Instruction Set Computer

Classic Microprocessor which we all know for its wide use in Personal Computers (PC).

This is a microprocessor which contains an MMU (Memory Management Unit) with complex sets of instructions, that is, instructions which are capable of generating the most "creative" memory accesses - convenient, but requiring many Clock cycles.

These types of processors are particularly suited for managing Operating Systems in Multitasking.

RISC - Reduced Instruction Set Computer

This is the new technology which is opposite the CISC, that is, a Microprocessor which contains a reduced MMU capable of generating simple but fast memory accesses.

This technology was developed when the difference between the speed of the processors and memory speed became significant, therefore it became indispensable to develop technologies which would optimise memory accesses, but these technologies were very difficult to implement in CISC processors due to their complex sets of instructions.

And so the RISC was developed, an extremely high performance processor in memory accesses which is largely used in Real Time application as well as, thanks to it low need for dissipation, in stressful industrial environments.

Microprocessors can be divided mainly into 3 families:

DSP, CISC and RISC

Without getting too technical, we can described the difference between these three families as follows:

DSP - Digital Signal Processor.

Microprocessors optimised to execute algorithms in an extremely efficient manner which allow handling of sampled signals.

These are particularly used in instruments of measurement where complex mathematical calculations are required such as a "Fourier Transform" or band filters for Multiplexers in the telephony sector or for analysis of Radar data, Sonar data, Spectra analysis, etc.

CISC - Complex Instruction Set Computer

Classic Microprocessor which we all know for its wide use in Personal Computers (PC).

This is a microprocessor which contains an MMU (Memory Management Unit) with complex sets of instructions, that is, instructions which are capable of generating the most "creative" memory accesses - convenient, but requiring many Clock cycles.

These types of processors are particularly suited for managing Operating Systems in Multitasking.

RISC - Reduced Instruction Set Computer

This is the new technology which is opposite the CISC, that is, a Microprocessor which contains a reduced MMU capable of generating simple but fast memory accesses.

This technology was developed when the difference between the speed of the processors and memory speed became significant, therefore it became indispensable to develop technologies which would optimise memory accesses, but these technologies were very difficult to implement in CISC processors due to their complex sets of instructions.

And so the RISC was developed, an extremely high performance processor in memory accesses which is largely used in Real Time application as well as, thanks to it low need for dissipation, in stressful industrial environments.

SISTEL SERVCE srl - Via Sgittario 3/3 | 40037 - Sasso Marconi (B0) - Italy

Link : History Museum (it)