History

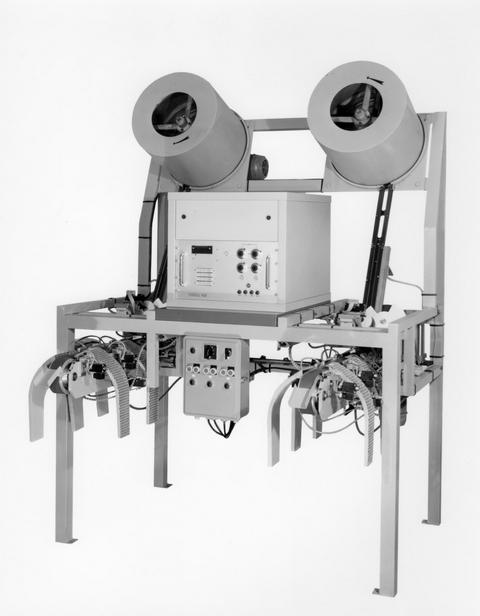

1978 - PHOCAL 200

The first Phocal is born

Features:

2 Channels

6 Selections

Cameras: CCD 1.024 points (32x32)

Production: 18.000 Washers/hour

Processor: Motorola 6800 - 8 Bit

Operator interface: Thermal Printer

Lights Control: Manual

Features:

2 Channels

6 Selections

Cameras: CCD 1.024 points (32x32)

Production: 18.000 Washers/hour

Processor: Motorola 6800 - 8 Bit

Operator interface: Thermal Printer

Lights Control: Manual

1984 - PHOCAL 200 serie 2

Finally the terminal

Features:

2 Channels

6 Selections

Stampers: For 1 class

Cameras: CCD 16.384 points (128x128)

Production: 32.000 Washers/hour

Processor: Motorola 6809 - 8/16 Bit

Operator int.: B/W Graphic terminal

Lights Control: Manual

Features:

2 Channels

6 Selections

Stampers: For 1 class

Cameras: CCD 16.384 points (128x128)

Production: 32.000 Washers/hour

Processor: Motorola 6809 - 8/16 Bit

Operator int.: B/W Graphic terminal

Lights Control: Manual

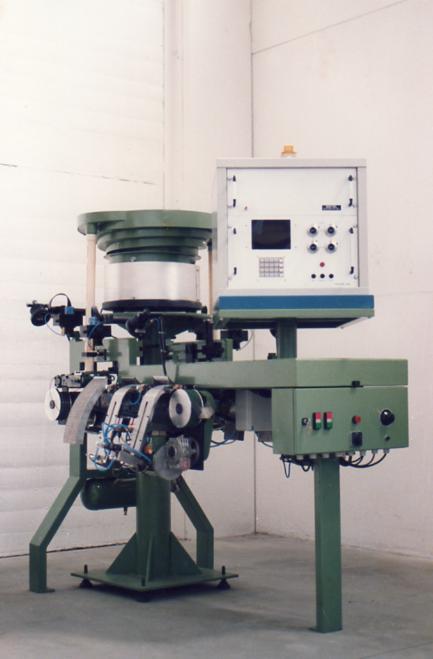

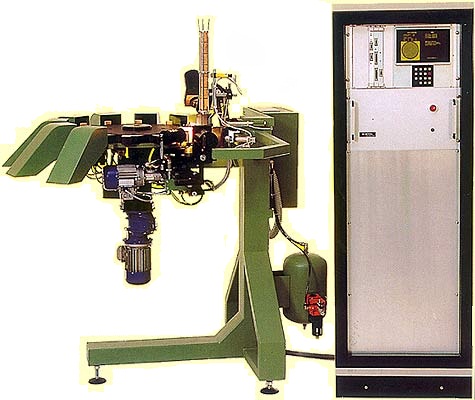

1987 - PHOCAL 400

The PHOCAL 400 series arrives, so innovative that not even we could have imagined the success that it would have.

With it productivity and capability of stamping all of the classifications, it revolutionised the market of the technical stopper.

So successful that even the competition had to brazenly copy this mechanical project in order not to be left out of the market.

Features:

1 or 2 Channels

6 Selections

Stampers: For all classes

Cameras: CCD 36.864 points (192x192)

Production: from 26 to 52.000 Washers/hour

Processor: Motorola 68020 - 32 Bit

Operator int.: B/W Graphic terminal

Lights Control: Automatic

With it productivity and capability of stamping all of the classifications, it revolutionised the market of the technical stopper.

So successful that even the competition had to brazenly copy this mechanical project in order not to be left out of the market.

Features:

1 or 2 Channels

6 Selections

Stampers: For all classes

Cameras: CCD 36.864 points (192x192)

Production: from 26 to 52.000 Washers/hour

Processor: Motorola 68020 - 32 Bit

Operator int.: B/W Graphic terminal

Lights Control: Automatic

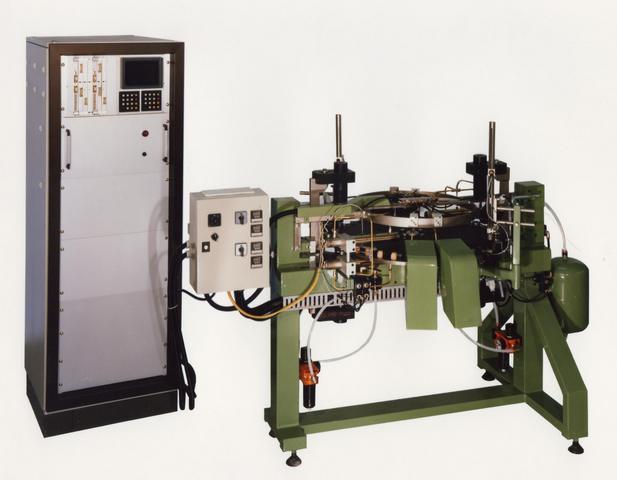

1992 - PHOCAL 340 B

"Boleado" stopper heads selector

Features:

2 Channels

3 Selections

Stampers: For all classes

Cameras: CCD 36.864 points

Production: 20.000 Stopper/hour

Processor: Motorola 68020 - 32 Bit

Operator int.: B/W Graphic terminal

Lights Control: Automatic

Features:

2 Channels

3 Selections

Stampers: For all classes

Cameras: CCD 36.864 points

Production: 20.000 Stopper/hour

Processor: Motorola 68020 - 32 Bit

Operator int.: B/W Graphic terminal

Lights Control: Automatic

1993 - PHOCAL 340 T

Champagne and 1+1 stopper heads selector

It is the prelude to the lucky 400 series

Features:

2 Channels

6 Selections

Production: 30.000 Stopper/hour

It is the prelude to the lucky 400 series

Features:

2 Channels

6 Selections

Production: 30.000 Stopper/hour

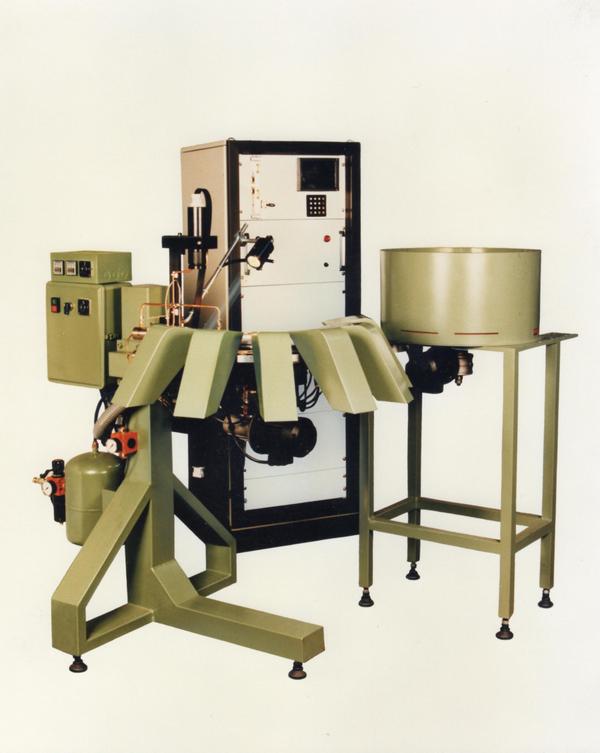

1994 - PHOCAL 430

The innovative Motorola 68030 processors arrive, equipped with double Cache Memory which allows significant Software innovations and above all the possibility of managing three cameras. With this the lucky PHOCAL 430 series is born, a machine for selection of Champagne and 1+1 stoppers

Interface: B/W Graphic Video Panel (no longer monitor)

Features:

1 Channels

7 Selections

3 CCD cameras 65.536 points (Heads and Body)

Production: 12.500 Stopper/hour

Processor: Motorola 68020 - 32 Bit

Operator int.: B/W Graphic video panel

Lights Control: Automatic

Interface: B/W Graphic Video Panel (no longer monitor)

Features:

1 Channels

7 Selections

3 CCD cameras 65.536 points (Heads and Body)

Production: 12.500 Stopper/hour

Processor: Motorola 68020 - 32 Bit

Operator int.: B/W Graphic video panel

Lights Control: Automatic

2000 - PHOCAL TT

PHOCAL 430 TT, a machine for reading technical stopper heads such as 1+1, 0+2 and Agglomerate.

Features:

Single body mechanics

6 Selections

2 CCD cameras 65.536 points (Only Heads)

Production: 18.000 Stopper/hour

Processor: RISC

Operator int.: B/W Graphic video panel

Lights Control: Automatic

Features:

Single body mechanics

6 Selections

2 CCD cameras 65.536 points (Only Heads)

Production: 18.000 Stopper/hour

Processor: RISC

Operator int.: B/W Graphic video panel

Lights Control: Automatic

From 1994 to 2000 no new models were created, unlike the electronics which in 1997, with the Motorola 68040 Microprocessor, the 4th generation is born. With this generous microprocessor the foundation was created for many algorithms which are still used today.

The year 2000, on the other hand, was the year of great changes: RISC Processors and Digital cameras

The year 2000, on the other hand, was the year of great changes: RISC Processors and Digital cameras

2002 - PHOCAL 420 Z

The Phocal 420Z, a machine for the selection of spoked cork washers, would be the first one to mount LED illuminators

Features:

6 Selections

3 CCD Cameras 65.536 points

Production: 22.000 Washers/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: LED with automatic control

Features:

6 Selections

3 CCD Cameras 65.536 points

Production: 22.000 Washers/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: LED with automatic control

2002 - The year of the LED

Finally LED!

The advantage of the LEDs is that they emit cold light which is completely free of infrared. Thanks to this characteristic it is possible to read all of those defects which are not very dynamic much easier, such as earth, stains, bellies and wood.

Not long after this the BLUE light LEDs came out which would help enhance those defects with a red base colour even better.

2006 - PHOCAL 530 TC

The PHOCAL 530 TC, a machine for selection of NATURALI and 1+1 stoppers, is born with all of SISTEL's most innovative developments and a brand new and exclusive feeding system.

Over the years this machine would pay for itself by leading us with dignity through an unprecedented period of economic slump.

Features:

Single body mechanics

4 or 5 Selections

3 CCD Cameras 65.536 points (Heads and Body)

Production: 9.000 Stopper/hour

Processor: RISC

Interface: 6" Colour LCD TFT Panel

Lights: LED with automatic control

Over the years this machine would pay for itself by leading us with dignity through an unprecedented period of economic slump.

Features:

Single body mechanics

4 or 5 Selections

3 CCD Cameras 65.536 points (Heads and Body)

Production: 9.000 Stopper/hour

Processor: RISC

Interface: 6" Colour LCD TFT Panel

Lights: LED with automatic control

2007, an extremely important year for SISTEL.

The extremely precious cooperation with EUROVITA Rappresentanze lda is born which takes us into a great package of information and specific experience. EUROVITA works in close contact with us, allowing us to develop an incredible quantity of work and software which will resolve many problems connected to quality control.

All of the machines will benefit greatly from these new developments, specifically the 420 Washers, 430 Champagne and 1+1 and the 530 Natural and 1+1.

The extremely precious cooperation with EUROVITA Rappresentanze lda is born which takes us into a great package of information and specific experience. EUROVITA works in close contact with us, allowing us to develop an incredible quantity of work and software which will resolve many problems connected to quality control.

All of the machines will benefit greatly from these new developments, specifically the 420 Washers, 430 Champagne and 1+1 and the 530 Natural and 1+1.

2008 - NEW PHOCAL 430

Features:

Single body mechanics

7 Selections

3 CCD cameras 65.536 points (Heads and Body)

Production: 12.000 Stopper/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: LED with automatic control

Single body mechanics

7 Selections

3 CCD cameras 65.536 points (Heads and Body)

Production: 12.000 Stopper/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: LED with automatic control

2010 - PHOCAL 530 JPA

The PHOCAL 530 splits itself in two, and the JPA joins the TC

Features:

Single body mechanics

4, 5 or 8 Selections

3 CCD Cameras 65.536 points (Heads and Body)

Production: 9.000 Stopper/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: LED with automatic control

Features:

Single body mechanics

4, 5 or 8 Selections

3 CCD Cameras 65.536 points (Heads and Body)

Production: 9.000 Stopper/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: LED with automatic control

From 1978 until today, here is the history of the most significant PHOCAL projects...

2012 - NEW PHOCAL 420 n

Features:

Single body mechanics

6 Selections

2 CCD cameras 65.536 points (Heads and Body)

Production: 26.000 Stopper/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: Stroboscopic and Polarized Low consumption blue LED

Single body mechanics

6 Selections

2 CCD cameras 65.536 points (Heads and Body)

Production: 26.000 Stopper/hour

Processor: RISC

Interface: 10" Colour LCD TFT Panel

Lights: Stroboscopic and Polarized Low consumption blue LED

2014 - PHOCAL mPH

The Phocal uPH (micro PHocal) was specifically created for checking “dry year” on the body of the disk.

Wood and “dry year” have always been among the major causes of controversy in the Champagne cork,

Features:

Single body mechanics

3 Selections

1 CCD Camera 65.536 points

Production: 12.000 Stopper/hour

Processor: RISC

Interface: 6" B/W LCD TFT Panel

Lights: LED with automatic control

Wood and “dry year” have always been among the major causes of controversy in the Champagne cork,

Features:

Single body mechanics

3 Selections

1 CCD Camera 65.536 points

Production: 12.000 Stopper/hour

Processor: RISC

Interface: 6" B/W LCD TFT Panel

Lights: LED with automatic control

2016 - UNICA

Machine that was created to control the weight and size of natural cork stoppers and technical corks.

Features:

Single body mechanics

5 Selections

Production: 17.500 Stopper/hour

Acquisition: 7x12Bit A/D Converter

CCD with Laser barrage

Processor: RISC ColdFire

Operator Interface: 5" B/W XVGA

Features:

Single body mechanics

5 Selections

Production: 17.500 Stopper/hour

Acquisition: 7x12Bit A/D Converter

CCD with Laser barrage

Processor: RISC ColdFire

Operator Interface: 5" B/W XVGA

2018 - UNICA-R

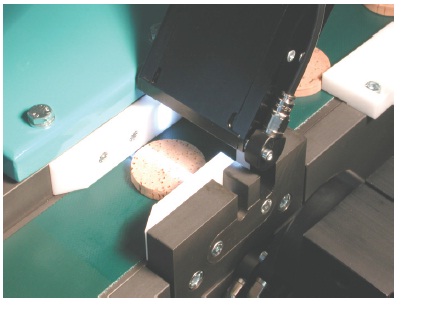

UNICA-R is an automatic machine that derives from the experience and precision of its sister UNICA and is designed to check the weight of 34mm diameter cork washers.

UNICA_R ranks "non-compliant" from those "compliant" in 3 divisions: Conform, Heavy, Light.

Features:

Single mechanical body

3 Classifications

Production: 8,000 Washers / hour

Acquisition: 12bit AD Converter

Processor: ARM

Operator Interface: Full Color Touch Pannel 7"

UNICA_R ranks "non-compliant" from those "compliant" in 3 divisions: Conform, Heavy, Light.

Features:

Single mechanical body

3 Classifications

Production: 8,000 Washers / hour

Acquisition: 12bit AD Converter

Processor: ARM

Operator Interface: Full Color Touch Pannel 7"

SISTEL SERVCE srl - Via Sgittario 3/3 | 40037 - Sasso Marconi (B0) - Italy

Link : History Museum (it)

2017 - CALIBRA

Machine for the conformity check of cork stoppers of all sizes.

Light, compact and precise, divide the caps into 4 Classifications:

Conform, Height, Diameter and Color

Features:

Single body mechanics

5 Selections

Production: 18.000 Stopper/hour

Custom

Acquisition: 7x12Bit A/D Converter

CCD with Laser barrage

Processor: ARM Cortex

Operator Interface: Full Color panel 7" Touch Screen

Light, compact and precise, divide the caps into 4 Classifications:

Conform, Height, Diameter and Color

Features:

Single body mechanics

5 Selections

Production: 18.000 Stopper/hour

Custom

Acquisition: 7x12Bit A/D Converter

CCD with Laser barrage

Processor: ARM Cortex

Operator Interface: Full Color panel 7" Touch Screen

2016 - UNICA 300 (Second generation)

Machine that was created to control the weight, size and color of natural cork stoppers and technical corks.

Features:

Single body mechanics

5 Selections

Production: 18.000 Stopper/hour

Custom

Acquisition: 7x12Bit A/D Converter

CCD with Laser barrage

Processor: ARM Cortex

Operator Interface: Full Color panel 7" Touch Screen

Features:

Single body mechanics

5 Selections

Production: 18.000 Stopper/hour

Custom

Acquisition: 7x12Bit A/D Converter

CCD with Laser barrage

Processor: ARM Cortex

Operator Interface: Full Color panel 7" Touch Screen